CNC Laser Cutting Machine

CNC Laser Cutting Machine

Laser cutting eliminates machining operation in production phase. So , many customers use this method for reducing production costs . The word “ laser ” is as an acronym for ” Light Amplification by Stimulated Emission of Radiation ” .

How Lasers Works ?

Basic Concepts

Some materials have instabilities to hold the electrons of their last orbit in their atoms . The energy level of these electrons changes due to absorption of energy . This change causes the releasing of photons and if the quantity of these photons rose to a sufficient level , they can cut materials .

In practice , a tube containing active substances which can be in solid , liquid or gas form excited by a high energy pulse source. In fact , this tube resonate the instability of its contents . Excited atoms inside the tube go back and forth between two ends of the tube which are semi reflected mirrors . This movement itself causes amplification of atoms energy . Finally high energy atoms pass through one of end-mirrors and produce laser .

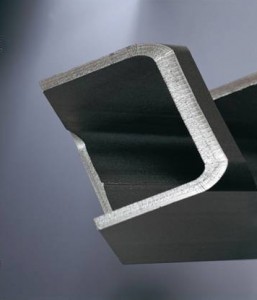

Laser beam hits the solid surface and causes direct conversion of solid to the gas (sublimation) due to its high energy . This phenomenon reduces the heat-affected zone ( HAZ ) and so causes a direct cutting line without distortion .

–

–

Laser Advantages:

1- Very fast cutting

2- Low cost

3- Nice and smooth cutting edges, with low distortion

4- Flexibility in cutting various types of materials.

Laser cutting has certain advantages compared to Plasma cutting . Laser cutting is much more accurate and uses less energy . Level of accuracy and quality of edges are better than of traditional cutting methods . It is worth mentioning that in laser cutting the workpiece contamination is greatly reduced .

–

–

Laser Cutting Software :

1- Importing various DWG and DXF file format .

2- Preview the file before opening and saving .

3- Storage and retrieval of cutting data after processing .

4- Reviewing saved files by TCMC software in all CAD setting programs .

5- Full-screen mode for full view of the drawings .

6- Execute arbitrary processing of all or part of the crop : Scale , Rotate , Move , and Delete .

7- Create and add a pattern using available templates .

8- Edit and save new templates by the user .

9- Archiving and viewing history of all processing operations without limitation for recovery purposes .

10- Define preheat time , preheat appendage and cutting priority .

11- Smart processing of shapes for minimizing sheet settings .

12- Determine dimensions of the sheet as you wish .

13- Defined margins and invalid areas on the sheet ( Sheet Alignment )

14- Determining angle of sheet on the table for ease of sheet loading ( Nesting )

15- Calculate the optimal layout of the sheet to reduce waste .

16- Determine the number and spacing of shapes .

17- Determine the starting point for cutting and cutting direction ( Flip Nesting ) .

18- Rotate shapes in the layout relative to each other ( Manual Nesting ) .

19- Processing single row and columnar mode of the layout : delete , move and rotate .

20- Defining the priority for cutting in the layout .

21- Storing and viewing of log ( history of processing operations ) .

22- Zoom in and Zoom out and Auto Moving .

23- Automatically displays the current coordinates of the cutting place on the center of the display .

24- Forward and backward cutting and stop command .

25- View , Layout , cutting and . . .

26- Graphical view of the part during cutting operation .

27- Continue cutting from the previous position .

28- Hand-cutting, with free 360 ° freedom .

29- Hand movements during automatic cutting .

–

–

| Max cutting area | 500*500mm | 1300*2500mm | 1500*3000mm |

| Repeat position accuracy | ±0.02mm | ±0.08mm | ±0.10mm |

| MAX Laser Power (w) | 600 | 600 | 600 |

| Wavelength | 1064nm | 1064nm | 1064nm |

| Max. cutting thickness | Stainless steel 4mm, carbon steel 6mm | Stainless steel 4mm, carbon steel 6mm | Stainless steel 4mm, carbon steel 6mm |

| Min Cutting line width | 0.15mm | 0.15mm | 0.15mm |

| MAX Cutting speed | 3000mm/min | 3000mm/min | 3000mm/min |

| Electricity consumption | ≤ 20KW | ≤ 20KW | ≤ 20KW |

| Power supply | 380V/50Hz/60Hz/60A | 380V/50Hz/60Hz/60A | 380V/50Hz/60Hz/60A |

| Cooling System | Water | Water | Water |